DRAGOON PANZERS

THE AIM OF THE PROGRAM

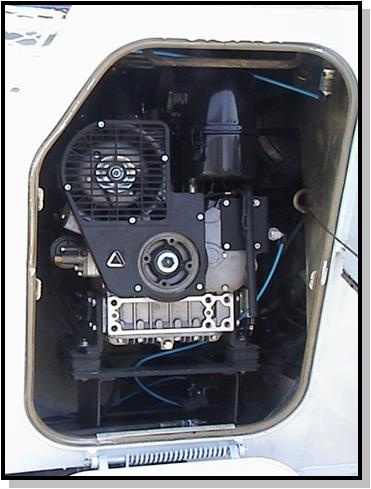

Centrifugal type water pump, with 7.5 to 15 bar operating

pressure and 1000 lt/min flow capacity at 7000 rpm at 10

bars has been mounted. All parts in contact with water

are made of corrosion resistant bronze and the impeller

shaft is made of stainless steel and coated with ceramic

material at bearings against to high speed wear.

The Pump is driven by a separate diesel

engine.

Pump and all piping can be drained completely.

Due to restricted space of pump unit

compartment, to achieve necessary air

circulation for the pump engine, Pump Unit

dimension is kept 50 cm in width,105 cm in

height and 65 cm in height.

Engine is diesel with 3 cylinders, 4 stroke, air

cooled and rated minimum 35 HP.

MODIFICATIONS APPLIED TO THE PROTOTYPE UNIT

THE PUMP PERFORMANCE HAS BEEN INCREASED.

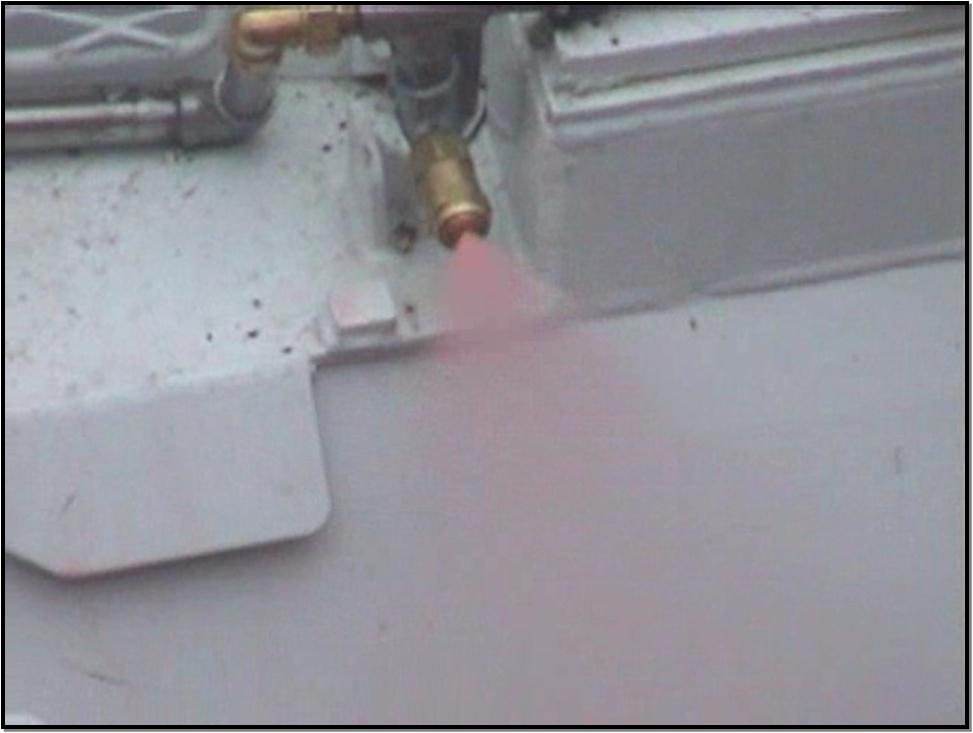

In order to protect Panzer outer structure against flammable material and possible fire attacks, a foam-water extinguishing system has been mounted. The system consists of, a control panel, one 40 liter foam tank, eductor, valves, piping and upper deck sprinklers, which are capable of foam-water spraying to the whole upper deck.

In addition to the upper deck sprinklers, foam nozzles are installed on top of all tires.

Standardize the features of all panzer’s in user's inventory.

Enhance Water pump flow and pressure performances.

Add a self protection feature against Molotov cocktails for the upper and lower deck with a foam-water extinguishing system.

Add a self protection feature for the approaching rioters with the Tear Gas Spraying system.

Install a Video Record and monitor system with front and rear cameras.

For trouble-free operation of the Water Cannon, replace the slip-ring system with the 360º rotation cable system.

Modify the front barrier, to be able to clear away the burning tires etc.

MODIFICATIONS APPLIED TO THE PROTOTYPE UNIT

To achieve 15 cm gap between ground and lowest position of the barrier, barrier hydraulic cylinders replaced with the new sized ones. Additionally, in order to avoid flammable and hazardous substances to enter under the vehicle, a steel sweeper has been mounted.

Driver’s window protection cages modified from fixed type to folding.

To prevent rioters approaching or climbing on to the Panzer, an OC (Tear) gas spraying system is mounted. The system consists of, OC gas tank, gas nozzles mounted all around the vehicle, Mixing - Proportioner System, Valves, Piping and the Control System.

Gas spraying starts automatically upon activating Gas Switch on the Control Panel.

STANDARDIZATION AND MODERNIZATION PROGRAMS

FOAM-WATER EXTINGUISHING SYSTEM HAS BEEN INSTALLED

CAMERA AND VIDEO SYSTEM HAS BEEN INSTALLED

MODIFICATIONS APPLIED TO THE PROTOTYPE UNIT

TEAR GAS SYSTEM HAS BEEN ADDED

In order to select and record any rioter(s), a video camera system has been installed on to the water-cannon nozzle. Camera will move vertical/horizontally as the cannon moves. High Resolution Auto Focus Zoom Colour Camera can shoot Under low ambient light conditions. The camera can capture under 1.0 lux luminous with horizontal 450 rows resolution and auto-white balance control. It is mounted into a special protected housing. Captured images can be monitored from an LCD Colour screen located in front of the turret operator. In addition, a video recorder with 24 hours recording times, has been furnished.

MODIFICATIONS APPLIED TO THE PROTOTYPE UNIT

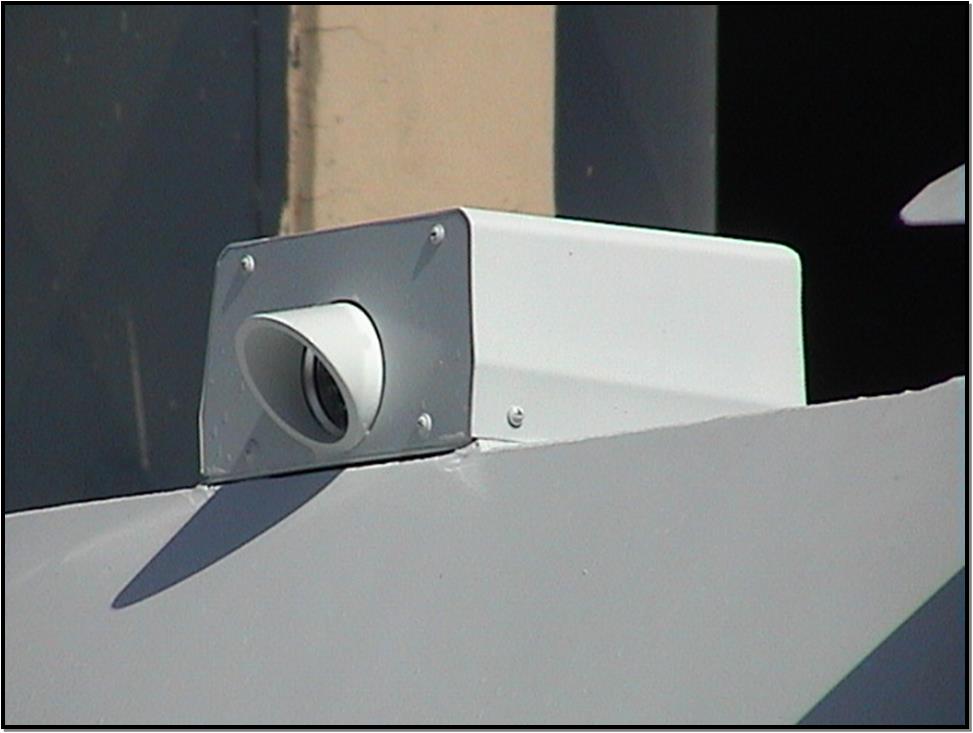

To increase vehicle maneuverability and safety, a fixed Rear View Camera System has been installed. The rear view, taken by this camera can be monitored by the Colour LCD Screen located in the driver's cabin. Rear camera has an ambient light sensitivity as well, and mounted into a special protected housing.

REAR CAMERA SYSTEM HAS BEEN MOUNTED

MODIFICATIONS APPLIED TO THE PROTOTYPE UNIT

MODIFICATIONS APPLIED TO THE PROTOTYPE UNIT